Towed belt conveyor, KLP

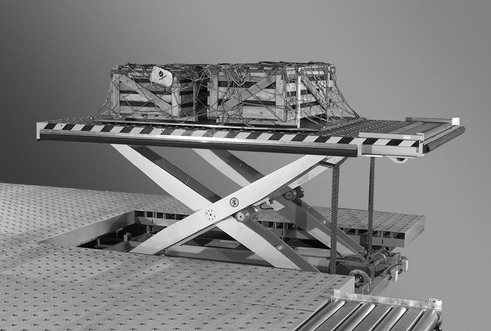

Towed belt conveyor KLP is designed for baggage, packaged cargo and mail reloading.

It comes with a combustion or electric engine.

There are three models: KLP-2,8, KLP-3,6, KLP-4,7. The maximum reachable height is from 2.8 to 4.7 m depending on the model. Minimum reachable height for all models is 1.1 m.

The towed belt conveyor consists of the following basic units:

- Truck with towbar;

- Conveyor arrows with hinged railings;

- Hydraulic system

- Power unit

KLP is equipped with parking brakes that are activated when the towbar is set to a vertical position.

The main control panel is located in the truck. The controlling and sensing devices are readable at any time of day.

The control module's graphic icons are the same as on the ANM 915.

The conveyor belt operates using reverse belt direction, the direction of the belt speed is adjustable, the arrows can be lowered without switching on the engine.

The arrow is equipped with railings made of stainless steel (on the left and on the right), which can be dismounted for oversize cargo and baggage. The side railing prevents the baggage falling down from the upper arrow platform during loading / unloading operations at the aircraft, providing there is no contact with the aircraft fuselage.

The body of the arrow is made of aluminium. There is a soft bar at the point where the crane touches the fuselage. The safety fence is made of wear-resistant material and doesn’t leave marks on the fuselage of the aircraft.

Slewing bearing is a turning device securing the 90° turn of the wheels in both directions. There are lubrication fittings inside the bearing. The bearing is produced by JOST (Germany).

There is a damper system on both ends of the arrow.

The conveyor belt is profiled and its surface has antiskid coating.

The coupling device consists of a bumper where it contacts the supporting surface and with a duplicating coupling device (a 14 mm rope with plastic covering with a hook С320А-165 fixed on the pole by a ring-bolt 24 with a threaded joint). The length of the rope is sufficient to prevent the tension of the road-train.

The back towbar is a manual coupling device with a spring loaded bolt. The towing device has a ring loop for coupling the preventer.

The wheels are pneumatic, at least R13, the wheel centre is strengthened.

The conveyor is powered by a “HONDA GX-390” gasoline engine with air cooling. The engine is started with a starter or manually.

The engine is installed on rubber shock absorber pads to avoid vibration.

The arrow turret is driven by a hydraulic engine with chain gear.

The emergency belt conveyor stop buttons are mounted on both sides of the arrow.

Specifications

| Property | Value |

|---|

Main advantages

-

Wide working temperature range

-

Experience and traditions

-

Multi-language support

-

Up-to-date design solutions

-

Price / Quality

-

In compliance with standards

EN

EN

RU

RU

_267x176_ff4.jpg)

_267x176_ff4.jpg)

-res-corr-web_341x254_71a.jpg)

_491x331_7ea.jpg)

_491x331_de1.jpg)

_491x331_7ea.jpg)

_491x331_de1.jpg)